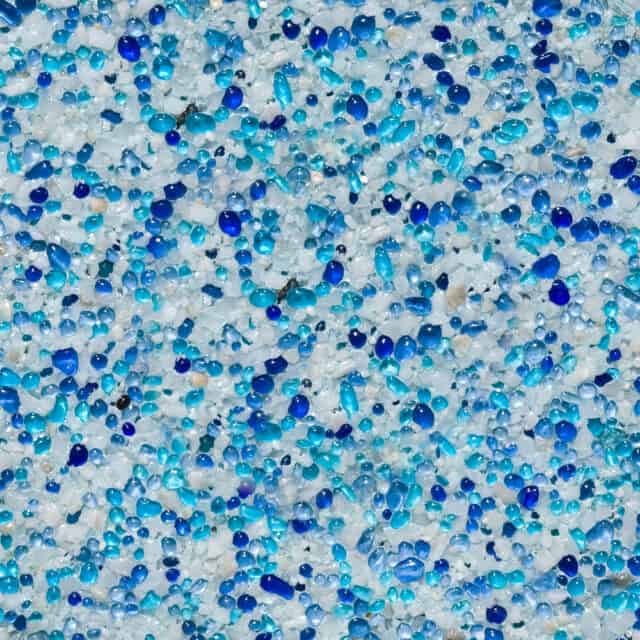

A premium glass pebble pool finish that will DELIGHT your customers, backed by award winning outstanding customer service.

You love your customers. So do we! We've been supplying our beautiful product to builders just like you for many years, so we know what you need, and we provide the knowledge and support to back it up.

products for builders

You'll love our premium range of glass pebble pool interiors.

Get more satisfied customers

Your customers will be absolutely thrilled with the end result - and that makes YOU look great too!

Save time and costs

You'll receive perfectly pre-mixed bags that only need water for installation - this helps you get the job done quickly and cost effectively.

Know that we've 'got your back'

When you need advice or support with your orders, our award winning team are with you every step of the way.

Our product range has you covered

stunning options

The Glass Pebble range is our most popular, but did you know we can supply beautiful pebbles, additives and products to keep your investment looking great?

FAQs for Builders

We know you'll have questions about our products and service - if we haven't answered them here, please get in touch!

Contact usI’ve been bitten by fancy blue pool interior products before. Is this going to stand the test of time?

Yes it certainly will. Our glass pebbles are fully coloured glass pebbles. They’re not painted. That means the colour will always stay in the glass no matter what. Beyond that, we stick as closely to possible to standard pebblecrete technology for our product. It will be every bit as durable, hardy and low maintenance as pebblecrete has been for you for the last 20 odd years.

What if I have bags left over at the end? Am I stuck with them?

Of course not. We fully refund any unused bags that are returned to us in a re-sellable condition – just get in touch!

Does the pool need to be started up any differently?

Yes, you’ll need to not add salt for the first four weeks, add 4 litres of Scale & Stain Eliminator and make sure the customer knows their brushing regimen.

We provide a copy of our start up instructions with EVERY order of our premixed and drymixed products. Contact us for a copy.

Can I water expose the product, or do I have to acid expose it?

You can certainly expose the surface by high pressure water, just like a normal pebble.

Is there a warranty for your product?

You bet! We offer a 10 year warranty for all our pool interiors. (Hot tip – you can extend your warranty by 12 months by registering your installation with us!)

Do I have to get a pebbler from a list of approved applicators?

No, absolutely not. Your pebbler is more than capable.

Do I need any special expertise to use this product?

No, if you’ve ever installed a pebble interior you can install Blue Glass Pebble Company’s glass pebble interiors. It is installed exactly the same way standard pebble is – from the scratch coat, to the troweling, to the exposing and to the acid wash – it’s all done the same way.

It looks good in a sample, but will it work that well for me when I use it?

We pride ourselves on having an extremely user friendly product which works first time every time for skilled applicators in any environment they may wish to use it. We are renowned industry wide for our customer service, commitment and reliability. We have countless happy customers in Darwin, Far North Queensland, Whitsundays, Mackay, Sunshine Coast, Brisbane, Gold Coast, NSW Coast, Sydney, Melbourne, Echuca, Perth, Broome, Cook Islands and Fiji. What this tells you is our product is versatile, adaptable and easy to use – no matter what the physical environment or the particular techniques of the applicators using it.

Want to buy our products? Get in touch!

We'd love to work with you on your next project, so fill in your details and let's get cracking.

- We provide award winning support

- We back our product 100%

- We're here to make YOU look good!

testimonials

Here's what builders and contractors just like you are saying

We've worked with hundreds of builders and contractors, and we're proud of the relationships we've created over the years.

Excellent premixed product used for past 10 years with outstanding results!

The Blue Glass Pebble Company provide an excellent premixed product that I have used over the last 10 years with outstanding results. They offer advice and service of the highest level.

Super helpful team and great products.

Super helpful team and great products.

Highly Awarded, Nationally Recognised

We've received some of the Australian pool industry's highest accolades over the years, as a direct result of our strong commitment to our products and services.

See All AwardsSPASA Queensland Awards of Excellence - Operational Excellence

HIGHLY COMMENDED - Lee Gibson

SPASA Queensland Awards of Excellence - Supplier Salesperson

HIGHLY COMMENDED - Michael Kettewell

SPASA Queensland Awards of Excellence - Supplier of the Year

HIGHLY COMMENDED - Blue Glass Pebble Company